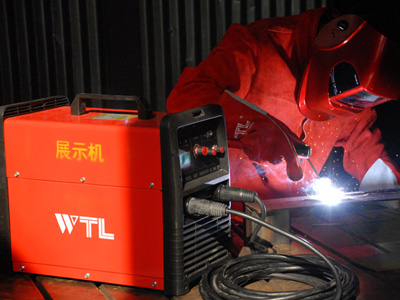

Established in 1993, WTL is one of the first manufacturers in China to engage in the research and development of inverter welding machines. With more than 25 years of experience in the welding industry, we are who other companies turn to in setting the standard for the design and sales of welding equipment for an array of different industries. Located in Pudong, Shanghai, our main factory supports an annual production capacity of 240,000 sets. To expand our already impressive production capacity, our newly-built factory in Songjiang district, Shanghai is in the process of being put to use, ensuring we can dramatically increase our production output. We also own and operate an advanced production line, SMD workshop, parts workshop, SMT manufacturing workshop and automatic warehouse, as well as an excellent R&D team and sales team, ensuring we can meet every customer need, every time. Due to the high quality and affordable price, our products are popular with customers both here in China and around the world.

We are ISO9001 certified, and are the proud owners of dozens of inventions and utility model patents, with all of our products conforming to CCC/CE/CSA/SAA standards, and we also aid our clients in getting them in compliance with the latest RoHS 2.0 certifications. With high quality products and advanced technology, our equipment is used for shipbuilding, construction, oil chemistry, nuclear and light industries innumerous countries around the world. Our main products include MMA, MMA/LIFT TIG, HF TIG, AC/DC TIG/MMA, MMA/TIG/MIG welders, plasma cutters and submerged arc welding machines.

Faced with the ever-changing market demand and challenges, WTL continues to innovate, offering our customers ever better products and services, backed by our more than 300 excellent and expert R&D, production and sales staff, led by 3 expert engineers who have over 10-years of experience, guaranteeing we offer our customers nothing but the best in products and quality.

We also carry out strict testing in the R&D processes to better ensure the quality and performance, long before machines ever leave our factory. Improvements are later made according to customer feedback about samples, and place machines into mass production only once we have satisfied customer requirements. It is our number one goal to consistently provide the best quality and performance in our products, from start to finish.

In addition to the tests carried out on each product, all products also undergo a strict inspection process that includes simulation of actual uses, ensuring all are compatible with CE/CSA/SAA certifications.

WTL has its own SMT workshop, parts workshop and production workshop with up to 10 production lines. This allows us to support an annual production of 240,000 machines when coupled with our 4 assembly lines.

The SMT workshop is equipped with 4 assembly lines, and is where we independently assemble high quality PCB boards using top equipment imported from trusted companies from around the world. The daily production capacity of the SMT workshop is 3000 units.

The SMT workshop includes metal processing and powder coating.

Metal processing: our metal processing workshop not only handles semi-finished welding products, but also customizes products to meet different industry needs, from food all the way to electrical work. All equipment, including the laser cutting machines, CNC punching machines and CNC bending machines are all imported from trusted international brands.

Our dust-free workshop is equipped with a Swiss GEMA automatic tunnel powder coating line, and we use automatic spraying machines for surface treatment on each product before they undergo a variety of tests, while our automatic warehouse ensures a better, more streamlined management and checking of raw material.

We are also proud of our sales team, and are proud to train them in technical expertise for machine design and development, allowing them to better communicate with clients to meet their needs for sales, service, and any other problems that may arise.

WTL Welding Equipment Manufacture Co. was successfully listed on the New Third Boards in 2018.